Electronics, telecommunications and other industries produce large amounts of industrial waste liquid containing precious metals, such as gold and silver. However, these metals can’t be effectively recycled because of its low concentration and the difficulty of recycling. Recently, Professor Liu Changjun’s research group in the School of Chemical Engineering and Technology at Tianjin University and the Tianjin University Chemical Collaborative Innovation Center (http://fuel.tju.edu.cn/) made a breakthrough in this field. They successfully extracted "floating gold film" and "floating silver film" in ionic liquid containing gold and silver efficiently, environmentally safely and selectively using electron reduction technology at room temperature. The gold ions can be extracted from solution mixed copper with iron, zinc and gold in 8 minutes and the recovery rate is as high as 99.96%.

The room-temperature electron reduction technology developed by Liu Changjun’s research group forms a number of electrons or other negatively charged ions by ionizing low-pressure gas at room temperature to stimulate the reduction reaction. Floating film of precious metals can be selectively formed on the surface of metal-ion-mixed solution quickly and efficiently by adding film forming material acting with gold and silver. The technique has been protected by applying for three patents and having one authorization. Related research papers were published in ACS Sustainable Chemistry &Engineering (4 (6), 3255–3260, 2016) this year.

This technology can extract gold efficiently even in gold-bearing solution the lowest mass concentration of only 0.01‰. The technology can not only reduce the pollution caused by the recovery of precious metals, but also selectively reduce only precious metals, leaving K, Ca, Cu and other ions in the solution. No reductant and toxic chemical reagents need to be added in the process. The equipment is not expensive and is easy to operate. The technology successfully makes the process of recycling precious metals environmentally safe, accurate and efficient.

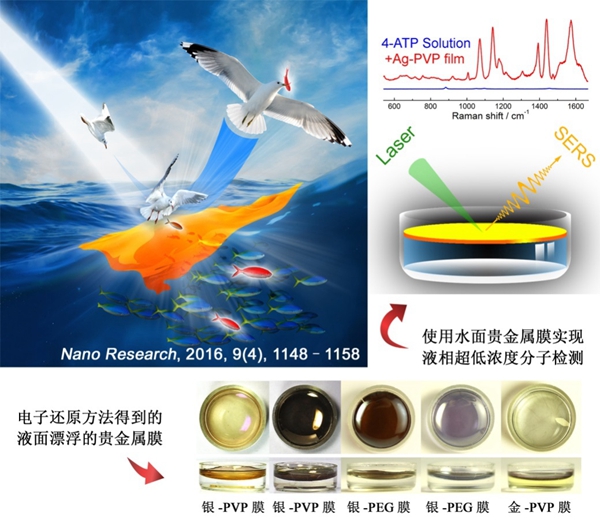

In addition to recycling gold and silver, the research group also applied for "floating gold film" and "floating silver film" patents to trace substance detection, for floating catalyst, etc. and has made a series of innovative research achievements. For example, the trace substances detection is to use the recycled floating silver film as the substrate of "Raman enhanced spectroscopy" and complete a variety of low concentration of chemical composition detections. Related research papers were published in Nano Research this year. (9 (4), 1148–1158, 2016).

In addition, the room-temperature electron reduction technology can also be applied for depositing Nano metal on thermal sensitive materials (gels, proteins, metal-organic frameworks, porous polymers, high surface area carbons, etc.), or for preparing metal combinations (polypeptide metal combinations, DNA metal combinations). For example, we can realize the preparation of “precious metal polypeptide film” by promoting biological molecules to assemble themselves with the room-temperature electron reduction technology. The process of the polypeptide self-assembly reactions can be quickly completed in 10 minutes, which usually needs several hours or even days. Meanwhile, the precious metal granules distribute equally on the film and its size is very small (about 2nm). These Nano metals or metal combinations show excellent photocatalytic hydrogen production performance and reduction of CO2 as catalysts (ACS Nano, 2015, 9 (11), 11258 - 11265). Its electrocatalytic performance for oxygen reduction is also very good (Nano Energy, 2016, 25, 26 - 33). The relevant paper will soon have a peer reference.